Four-wheel Tractor Large Subsoil Shovel Supports Customization

Product Type

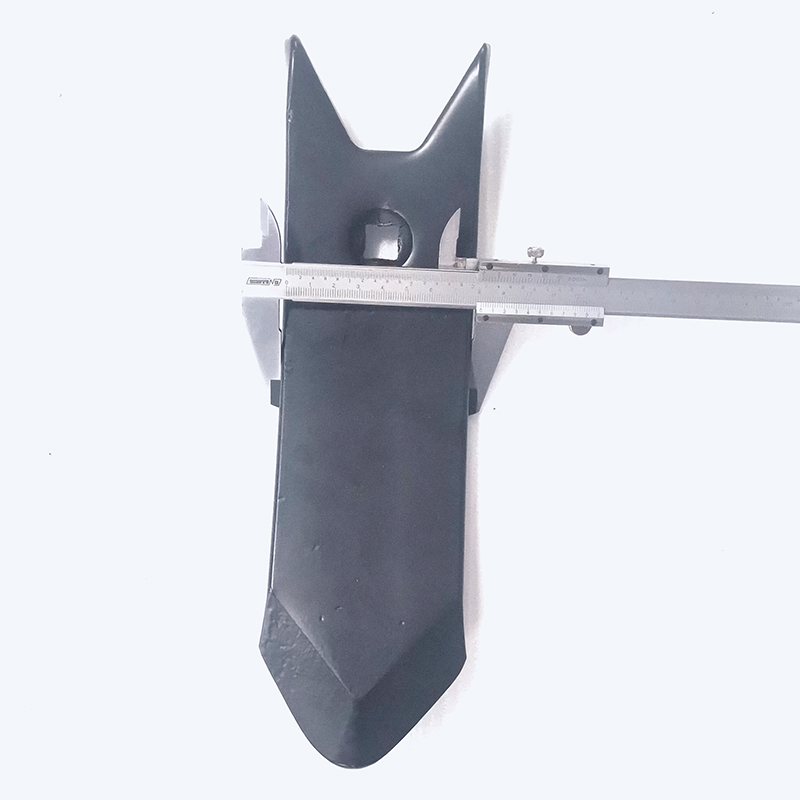

The subsoiling shovel consists of two parts: the shovel head (also known as the shovel tip) and the shovel column.

The shovel head is the key part of the subsoiling shovel. Commonly used types of shovel head include chisel shovel, duck foot shovel, double-wing shovel and so on.

The width of the chisel shovel is narrow, similar to the width of the shovel column, and its shape is flat and rounded. Circular ridge crushed soil performance is better, and has a certain effect of turning soil.

The flat-shaped work resistance is small, the structure is simple, the strength is high, the production is convenient, and it is easy to replace after wear. It is suitable for deep loosening between rows and comprehensive deep loosening.

Duck paw shovel and double-wing shovel have larger shovel heads, and these shovel heads are mainly used for deep loosening between rows. Two-wing shovels are more commonly used to loosen topsoil in layered subsoiling, and can also be used for subsoiling when soil strength is low.

Deep loosening shovel wear-resistant surfacing

The subsoiling shovel is subjected to alternating stress and contacts with sand, stubble and corrosive substances in the soil during the farming process, and the tip of the shovel is prone to serious wear and failure, of which 40% to 50% are caused by low-stress abrasive wear. of. After the subsoiling shovel is worn out, the performance of soil penetration will decrease, the stability of ploughing depth will deteriorate, the traction resistance and fuel consumption will increase, and the number of replacements will increase, thereby increasing the operating cost ratio.

Features

• The four-wheeled tractor is driven by the main power source, hollowing out the soil to ensure that it will not disturb the soil and damage the surface.keep the vegetation intact,

The tillage depth is 10cm below the soil surface

It can reach 25cm-45cm, when the recommended working depth is 30cm,

The power required is 35-45 horsepower: when the working depth is 70cm

Need power between 55-65 hp

Above, the operating speed is maintained at 3.0-5.0 km/h.

• Made of high quality boron steel,

High strengthening treatment: commonly used 30MnB5, 38MnCrB5.

• Heat treatment: HRC: 50+3.

Product Information

| Ref.Nr. | mm | Grs. | A mm | B mm | C mm | Matching nut |

| FJ16010-A D CA | 15 | 23.200 | 300 | 820 | 80 | 15015T |

| FJ16010-A I CA | 15 | 23.200 | 300 | 820 | 80 | 15015T |

| FJ16010-B D CA | 15 | 23.200 | 300 | 820 | 80 | 15015T |

| FJ16010-B I CA | 15 | 23.200 | 300 | 820 | 80 | 15015T |

Product Display